A UK company based in Sheffield, England, supplying marking, cleaning, welding, and cutting machines worldwide.

Easy to use with Integrated, bench-mounted & hand-held systems in most languages.

Global Suppliers of Etching, Engraving, and Cutting Machines

In this ever-mounting demanding world for track and trace on nearly all products. Traceability is useful before, during, and after development in several industries. It leaves a record of what has been done, so you don’t have to start traceability from the beginning. It makes it easier to assess risks and prevent mistakes during manufacture. It makes compliance a faster and easier process. In some cases, traceability is even mandated by governments. Regulations, using traceability can help to build high-quality products faster and to meet your needs. Within the manufacturing chain, many have already invested in stand-alone or fully automated production lines encompassing our integrated marking Systems, capable of engraving components moving on high-speed production lines. Components are marked with a unique ID, such as a Data Matrix code, QR-codes, 1 and 2D Bar-Codes, scanned and tracked throughout their production, assembly, and distribution processes. Industrial Marking Systems can provide a range of benefits to those people wanting to invest in industrial digitalisation. Benefits include faster productivity times as ‘bottle-necks’ are identified. Your data can be monitored, and poor-quality products are reduced as raw materials are tracked and recurring faults identified. OEM suppliers are under pressure to meet international quality standards that are increasingly being approved by manufacturers from Aerospace, Automotive Medical, Oil and Gas to name but a few throughout the supply chain, we at BELMARKING LTD have a wide range of Industrial Marking Systems available, to suit your manufacturing processes and budgets.

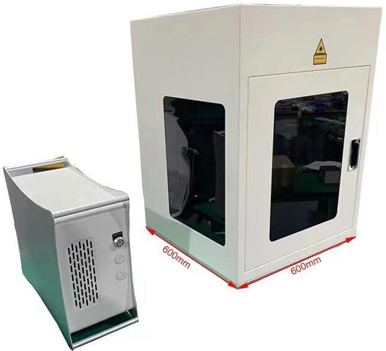

Large Laser Marking Machines – Fibre, Ultraviolet and CO2

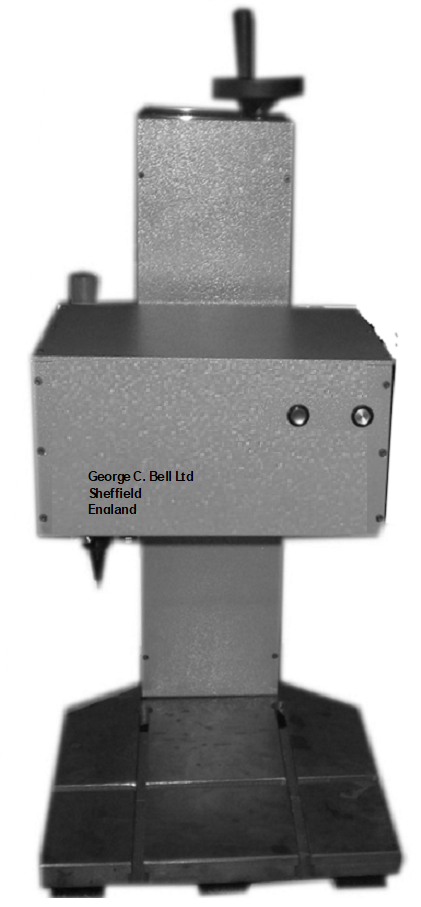

Dot peening Marking

Using a stylus to indent a series of dots on the surface of a material. The stylus is programmed to move across the surface and create characters, logos, or a Data Matrix code – a kind of ‘barcode’ that stores large amounts of data in a small area. Dot peen marking is fast and accurate and can mark through coatings or anodising on the material’s surface. It is particularly useful for permanently marking a Data Matrix code onto metal components. When using dot peening, the depth of the mark – which is a measure of legibility – depends on the marking power, marking gap, (the distance from the stylus tip to the workpiece), the distance between each dot, and the material hardness, and the stylus tip angle. The larger the marking gap, the deeper the mark. However, if the gap is too large then the stylus will start to stick – and drag the workpiece. This is solved by reducing the gap or increasing the marking force. While the stylus toughness, the tip angle is usually set at 90°, it can be made to suit your application at 60°, 90°, or 120°. while this will make a shallower mark, it will lengthen the life of the stylus. Bel-marking Ltd offers an extensive range of dot peen/pin marking machine

MT16C Series (Standalone Controller, no PC required

MT16C Series (Standalone Controller, no PC required

Stand based machine with Standalone 7” LCD Touch Screen

Printing Area : 150 mmx 100 mm

Support Plain/ Arc Marking (Line and Dot marking support)

Auto Serial Number, Graphics and 2D Barcode Support

Manufactured in the UK

Foot pedal control Switch

Manual Z axis Up and Down Marking Head Travel of 300 mm

Inscribe marking, a pneumatically actuated pin is driven into the metal surface and then moved through the metal – engraving an inscription in a continuous line. It is important to hold the work piece firmly to make a quality mark. Scribe machines need firm fixturing because they generate high cross forces during marking. Deeper marks are harder to make than light ones, and this can be caused by a few factors including marking force, and the radius and angle of the pin. Marking force is controlled by adjusting pneumatic pressure. It is usually set between 2 and 6 Bar but should not be turned up too high with fine stylus angles as this could ‘jam’ in the material If the tip is sticking in the material – causing the machine to stall – this can be remedied by reducing the air pressure or reducing the marking speed. Our Dot Peen/Pin machines are available in several configurations to meet your requirements.

The Dot peen machines are especially good as they can be used as bench-mounted systems and even used as a handheld portable unit. The hand-held variations are great for quick marks on larger products and can be used further away from their designated work space. The Dot Peens is used for logos, serial numbers, incremental serial numbers, barcodes, and data matrix codes. This has been one of the most popular affordable and go-to marking machines we have ever produced.

Bel MarkingBLX-C1series

Lasers are popular with our new and previous customers. They have enjoyed working with Dot peen machines but have often wanted to upgrade and improve their marking for traceability. Lasers can be used for marking just like the Dot peen machines but cleaner, more accurate, faster, and with less noise. Our Lasers are less expensive than some Dot Peen systems, The aesthetics of the Laser mark can enhance the value of your product. Over time similarly to the Dot Peen, these products earn their worth, Investing in laser machines will offer you a clear and accurate finish on all your products. We have lasers ranging from 5w to 100w there is always a model that is suited for your application. We can arrange to visit your workplace and work towards a solution to complement your requirements.

Having a fume extractor on a laser machine is important for several reasons:

All part of Belmarking’s service.

Bel Marking ECM machines

Chemical etching is one of the older marking methods where marks are put on your product for traceability or any reason you would like but the material is not altered. This is because no pressure or heat is used therefore the material is not affected. Chemical etching is one of the more economical ways of marking compared to Laser, hand stamping, and punching.

BEL-marking Ltd has been scaling new heights of success in Marking equipment. We have achieved expertise in the manufacturing of State-of-Art Marking Machines.

Marking Machines and Electrochemical/electrolytic Metal Etching Machine suppliers in Domestic and International markets. Our services and commitments to our customers will remain as dedicated as ever, and we will endeavor to supply all our marking & etching consumables to the highest possible standards with a fast reliable Global Service. True to the spirit of the company our products like marking instruments reflect the same quality and standard.