Who is George C. Bell?

We are a Sheffield-based company specialising in industrial engraving equipment, delve into the remarkable world of Lasers, Fibre, Ultraviolet (UV), and CO2 marking technologies in conjunction with Electrochemical and Dot Peen/Pin marking machines. This exploration aims to shed light on their applications, advantages, and contributions across various industries.

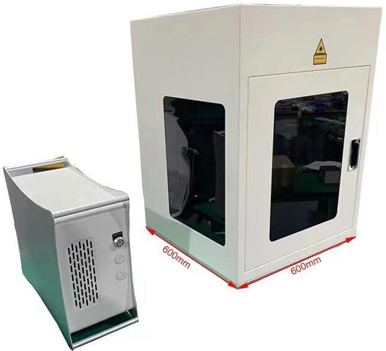

Laser Marking Technologies:

Industrial marking and Traceability Systems

Laser Cleaning System:

The operation of a 2D Mini Laser Cleaning Head involves several key steps:

1. Laser Emission: The cleaning head generates a laser beam, usually in the ultraviolet (UV) or infrared (IR) spectrum. The wavelength and power of the laser can be adjusted based on the material and type of contamination.

2. Beam Delivery: The laser beam is directed through optical components within the cleaning head, ensuring that it maintains its focus and intensity as it reaches the target surface.

3. Scanning Mechanism: The 2D scanning mechanism allows the laser to move across the surface in a controlled manner, covering the entire area that needs to be cleaned. This movement can be precisely controlled to ensure uniform cleaning without missing any spots.

4. Contaminant Removal: When the laser beam hits the surface, it rapidly heats the contaminants, causing them to evaporate or sublimate (transition from solid to gas) without damaging the substrate. This process is effective on a variety of contaminants, including rust, paint, oil, and more.

CO2 Lasers:

Applied on non-metallic materials, CO2 lasers excel in engraving, etching, and marking surfaces such as wood, glass, and plastics.

Ideal for high-speed applications, ensuring swift and accurate results.

Fibre Lasers:

Renowned for exceptional precision and reliability, fibre lasers are widely used for marking metals and alloys. High beam quality facilitates fine details and intricate designs. Fibre lasers offer numerous advantages, including high efficiency, superior beam quality, compact and robust design, low maintenance, and versatility in applications. Their precision, scalability, and reliability make them valuable tools across a wide range of industries, from manufacturing and automotive to aerospace and electronics. The benefits of fiber lasers in terms of operational efficiency, safety, and environmental impact further enhance their appeal as a modern solution for material processing.

Ultraviolet (UV) Lasers:

Improved Micro-machining Capabilities

The short wavelength allows better control over the ablation process, making UV lasers ideal for micro-machining applications. This includes drilling tiny holes, cutting thin materials, and creating micro-scale features with high precision. Optimal for marking heat-sensitive materials, UV lasers achieve high-contrast marks on plastics and certain metals. Compatibility with Automation

UV lasers are easily integrated into automated manufacturing systems, enhancing production efficiency and consistency. Their precision and repeatability make them suitable for high-volume and high-speed manufacturing environments.

Dot Peen/Pin Marking Machines:

Battery Operated Mechanical Marking:

This method utilises either pneumatic or electronic mechanisms, employing a driven pin to imprint surfaces with alphanumeric characters, logos, and diverse codes like DataMatrix and QR codes. Capable of adhering to GS1 standards for the medical industry marking.

Diverse Applications:

Commonly adopted in automotive, electronics, and medical industries for part serialisation and tracking.

Offers robust and cost-effective marking solutions.

Synergies and Integration:

Combining Laser Technologies:

Integration of CO2, Fibre, and UV lasers allows for a broader material compatibility range and diverse marking effects.

Enables tailored solutions for various industrial requirements.

Complementary Use with Electrochemical and Dot Peen/Pin:

Hybrid systems combining laser technologies with electrochemical, or dot peen/pin marking offer enhanced versatility.

Laser precision complements the depth and durability of electrochemical and dot peen/pin marking.

Advantages:

High Precision:

Laser technologies provide micron-level accuracy for intricate marking, while dot peen and electrochemical methods ensure deep and lasting impressions.

Versatility:

Combined technologies offer extensive material compatibility, meeting diverse industrial needs across both flat and irregular surfaces.

Speed and Efficiency:

Laser systems provide rapid marking, enhancing production throughput.

Dot peen and electrochemical methods offer efficient and reliable solutions for high-volume manufacturing.

Conclusion:

In the dynamic realm of industrial marking, the integration of Laser, Fibre, Ultraviolet, and CO2 technologies with Electrochemical and Dot Peen/Pin marking machines signifies a pinnacle of precision, versatility, and efficiency. These technologies play a crucial role in achieving durable, high-contrast marks on various materials, contributing significantly to product traceability, quality control, and overall industrial efficiency.